BOP Hoisting and Moving Device

![]()

BOP hoisting and moving device is specially designed for installation and disassembly of BOP. The company can provide BOP hoisting and moving device with a bearing capacity of 30~160 tons and a stroke of 3.2~10.4m or more longer.

This series BOP hoisting and moving device adopt the most classic oil cylinder type drive system, which has strong load capacity, safe and stable, simple structure, convenient maintenance, fewer vulner-able parts, low operating cost, reliable speed control, and no stall. At the same time, the unique quadruple range steel wire structure is adopted, which increases the lifting stroke, shortens the length size of the device, increases the forward and backward distance of BOP, more practical and more widely applicable.

Performance Characteristics :

| • Designed and produced in accordance with API 7K, and API certificate is obtained; | • Multiplication-range, long operating stroke and short body length; |

| • Cylinder structure is adopted, safe, stable and reliable; | • Equipped with explosion-proof valve, counterbalance valve and other hydraulic parts, multiple protection in order to prevent BOP unexpected fall down; |

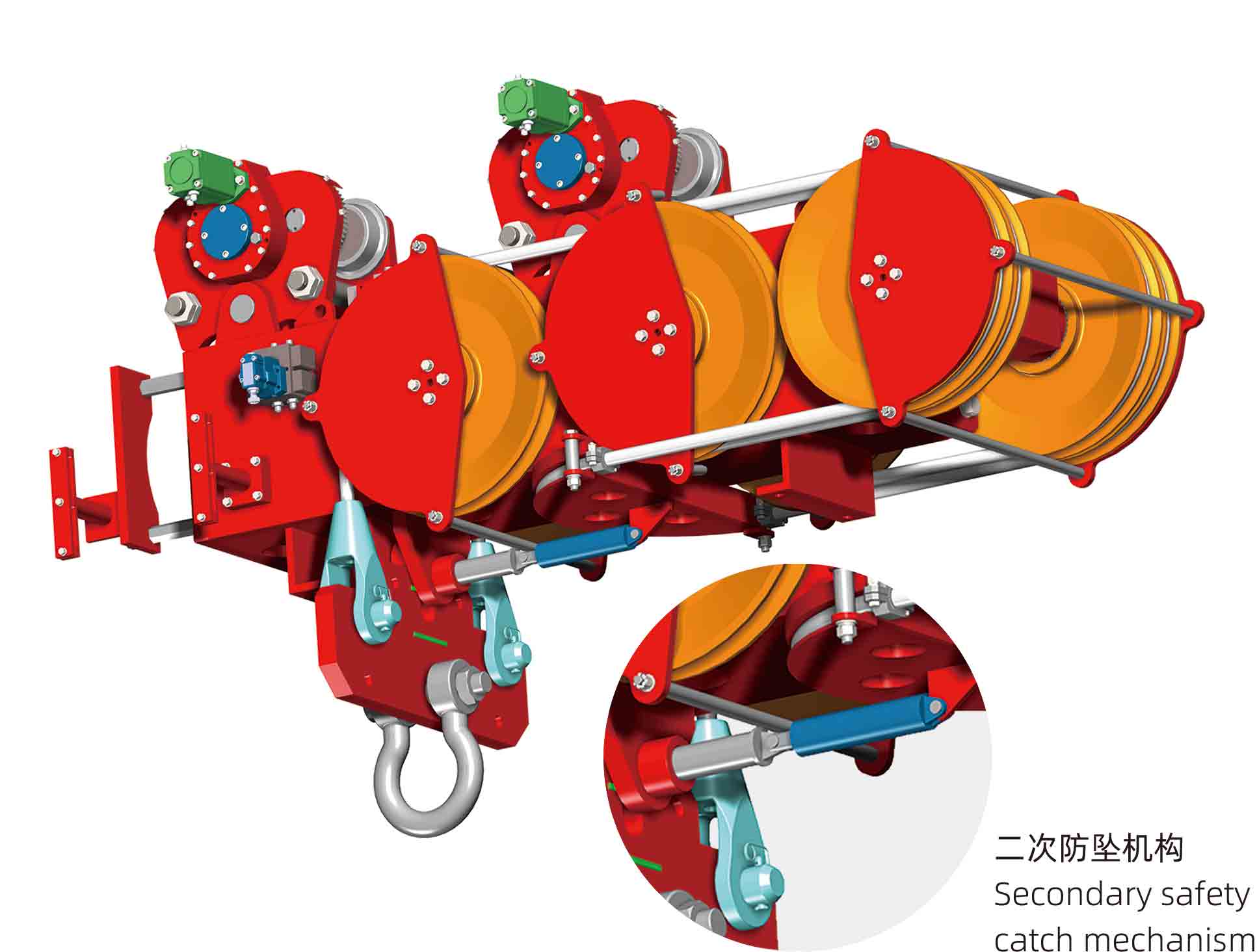

| • Secondary safety catch can be installed, making the operation safer and more reliable; | • The control panel can be equipped with a hydraulic emergency button to make sure nothing goes wrong. |

Technical Parameter:

|

Type |

Standard |

Hoist rating |

Lifting stroke |

Maximum hoisting speed |

Maximum translational speed |

Maximum operating pressure |

Maximum flow |

Diameter of rope |

|

FYS300 |

API 7K |

15×2 t |

4m |

1 m/min |

8 m/min |

18MPa |

25L/min |

24mm |

|

FYS500 |

API 7K |

25×2 t |

4/4.8m |

1 m/min |

8 m/min |

18MPa |

35L/min |

28mm |

|

FYS600 |

Team Standards |

30×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

35L/min |

32mm |

|

API 7K |

30×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

50L/min |

32mm |

|

|

FYS800 |

Team Standards |

40×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

65L/min |

32mm |

|

API 7K |

40×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

65L/min |

36mm |

|

|

FYS1000 |

Team Standards |

50×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

80L/min |

36mm |

|

API 7K |

50×2 t |

4.8/6.4/7.2/8.4m |

1 m/min |

8 m/min |

18MPa |

80L/min |

40mm |

|

|

FYS1200 |

Team Standards |

60×2 t |

4.8/6.4/7.2/8.4/9.6m |

1 m/min |

8 m/min |

18MPa |

95L/min |

36mm |

|

API 7K |

60×2 t |

4.8/6.4/7.2/8.4/9.6m |

1 m/min |

8 m/min |

18MPa |

95L/min |

44mm |

|

|

FYS1500 |

Team Standards |

75×2 t |

4.8/6.4/7.2/8.4/9.6/10.4m |

1 m/min |

8 m/min |

17MPa |

100L/min |

44mm |

|

API 7K |

75×2 t |

4.8/6.4/7.2/8.4/9.6/10.4m |

1 m/min |

8 m/min |

17MPa |

100L/min |

52mm |

|

|

FYS1600 |

Team Standards |

80×2 t |

4.8/6.4/7.2/8.4/9.6/10.4m |

1 m/min |

8 m/min |

18MPa |

120L/min |

44mm |

|

API 7K |

80×2 t |

4.8/6.4/7.2/8.4/9.6/10.4m |

1 m/min |

8 m/min |

18MPa |

120L/min |

52mm |